"The change we implemented (with help from CIRAS) eliminated factors that led to reduced product performance,

and we haven’t had any failures in the last two years."

- Joe Hadar, President, Hadar Manufacturing

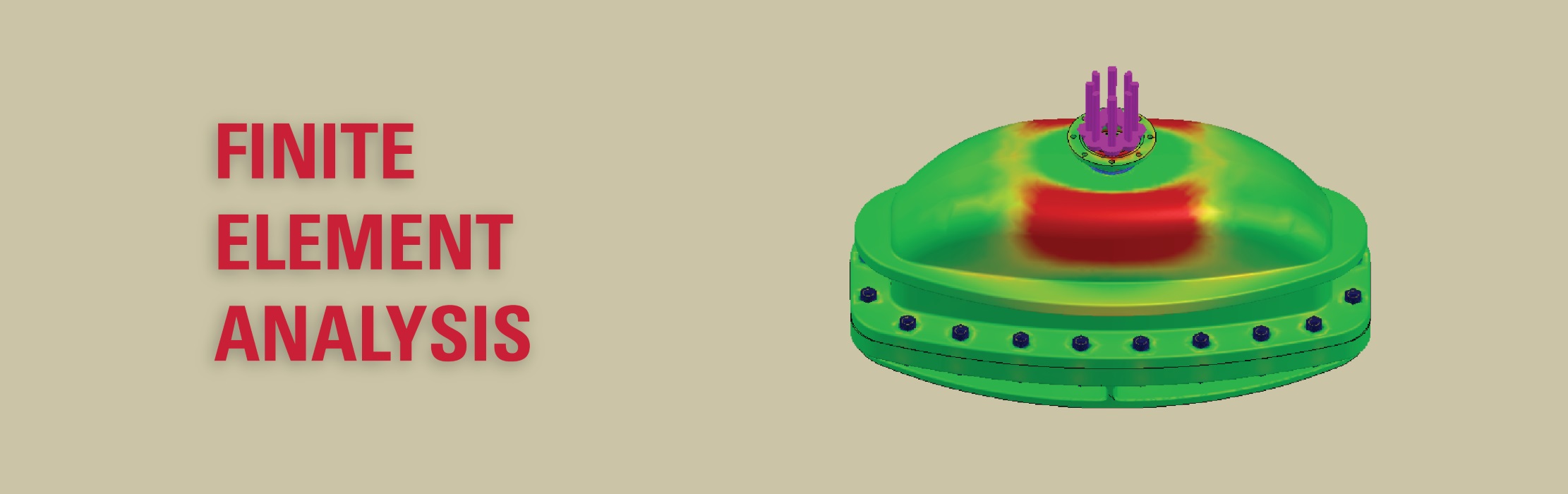

Improve Products and Processes with FEA

Iowa manufacturers with concerns about the safety or reliability of a particular part or product can explore its suitability for a particular purpose by using Finite Element Analysis (FEA).

CIRAS experts can help Iowa businesses use FEA simulations to evaluate performance of a product under a host of thermal, stress, vibration, and/or fatigue conditions. Engineers then can use this information to pinpoint weak spots in any particular design. This analysis helps companies explore options for new products and parts while using fewer resources to launch experiments or design prototypes.

Implementing finite element analysis can help Iowa manufacturers:

- Develop new products faster and at a lower cost

- Improve product quality

- Increase product life

- Provide greater product reliability

- Increase customer satisfaction

- Develop testing processes more easily

- Evaluate “what if” design scenarios without high costs

The CIRAS Engineering Team can work with Iowa companies to evaluate possible applications of FEA in product development and analysis, including a free on-site assessment.

To seek guidance about Finite Element Analysis or to schedule your no-cost assessment, contact your regional CIRAS Strategic Advisor or Project Manager John Roberts.

CIRAS provides several related services, including: